Make KSGER safe

Since this unit comes in different version and configuration you’ll need to make sure which of the changes apply to your unit.

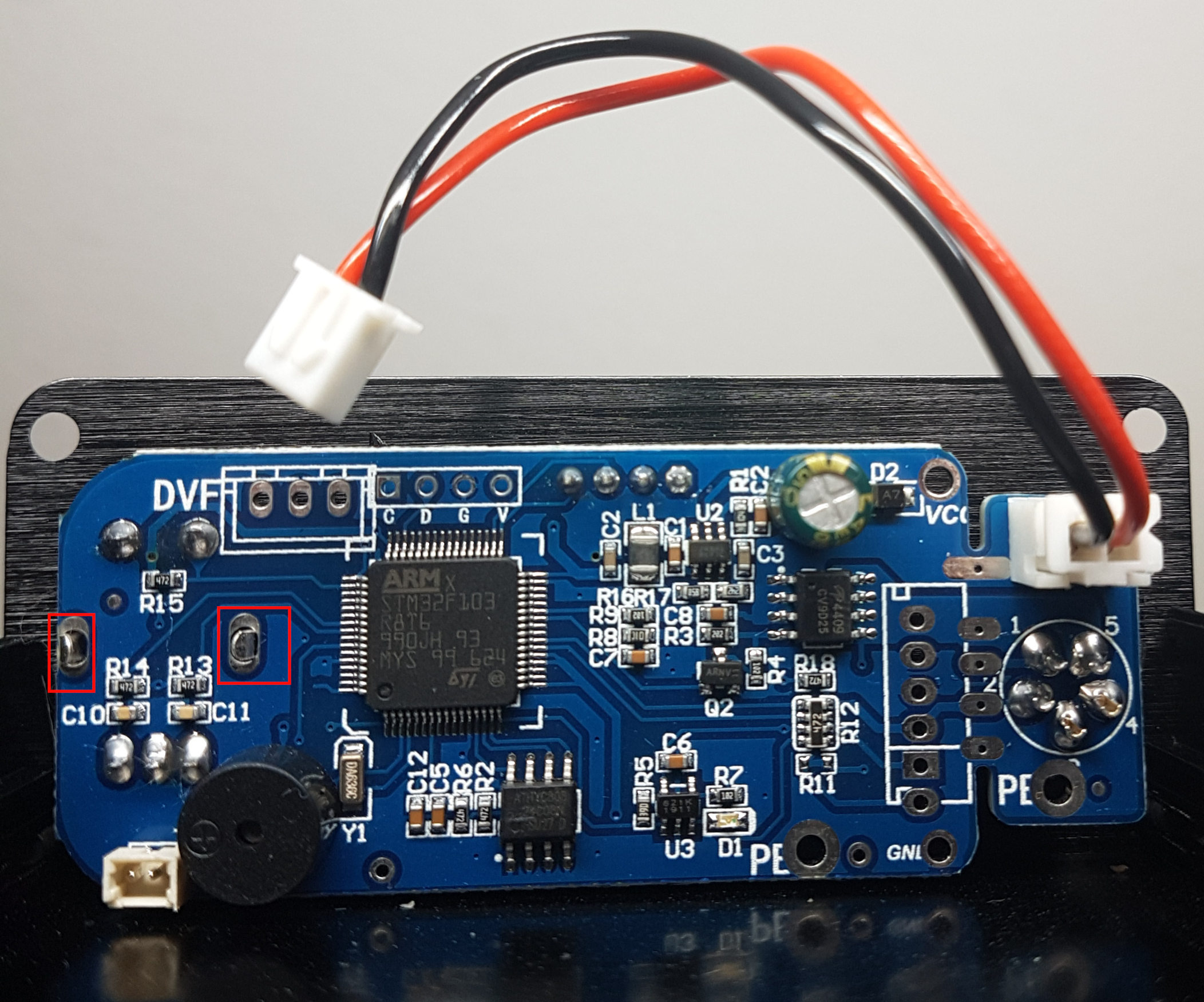

This steps were performed on the the following configuration of Ksger T12 Soldering station.

- Hardware Version 2.1S

- PSU version v2.04

- Aluminum case

What needs to be improved

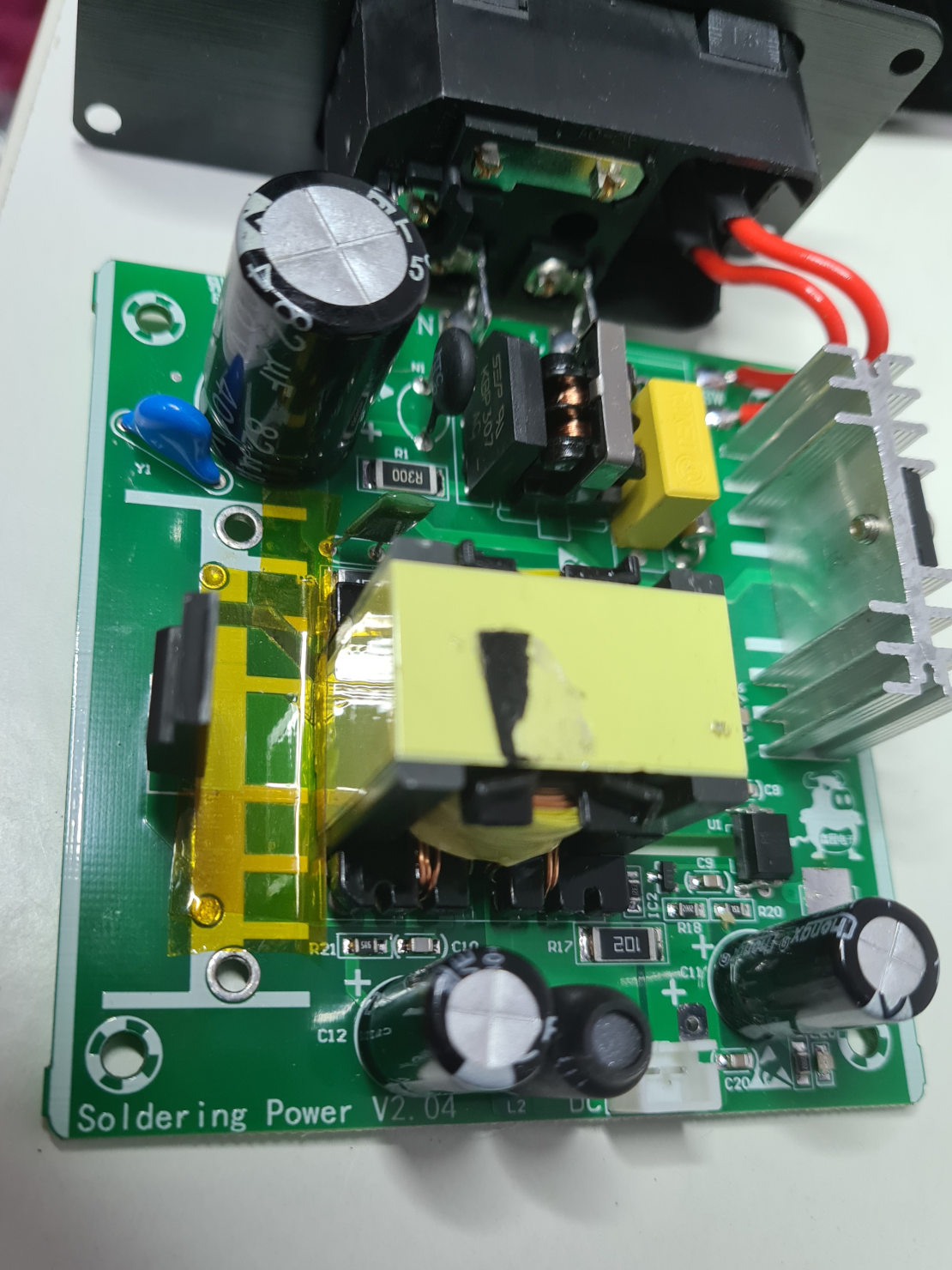

- Improve isolation of heatsink from high voltage track

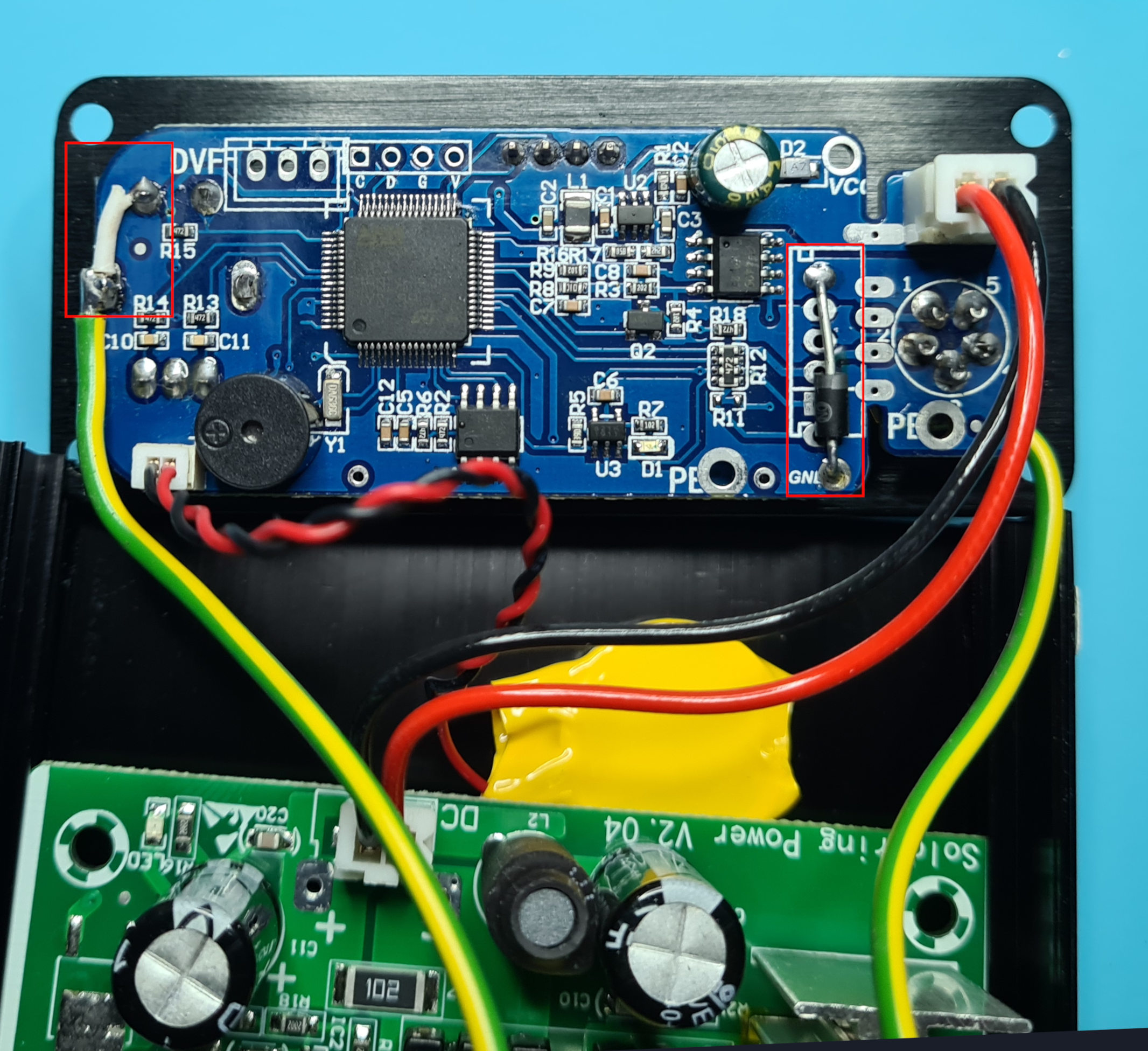

- Grounding of Encoder, GX12-5M shell, and casis.

- Add transient protection diode

- Improve display alignment.

Improve PCB high voltage track isolation from heatsink.

Grounding of Encoder and GX12-5M

Adding a transient protection diode.

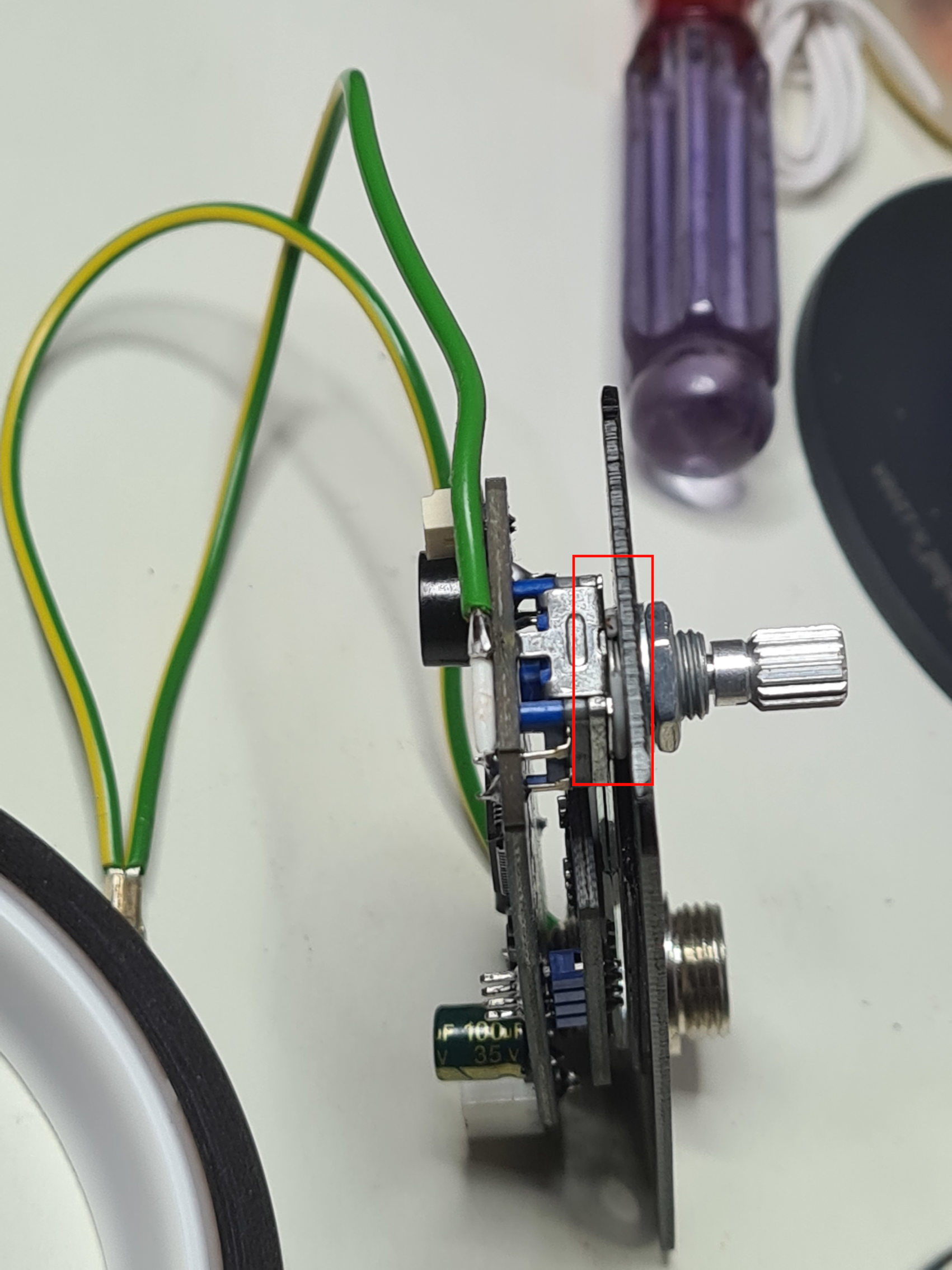

Improve OLED Display alignment w/ front panel.

To make the front pcb more parallel with the front panelI’ve added a spacer (a piece of solid wire) on the encoder side. Other option was to desoldered the GX12-5M and relocate the washer to the front side, but this one requires a lot of effort. The display was resoldered so that would sit more closely with the cutout in the front panel

No comment

Say something

Thank you

Your post has been submitted and will be published once it has been approved.

OK

OOPS!

Your post has not been submitted. Please return to the page and try again. Thank You!

If this error persists, please open an issue by clicking here.

OK